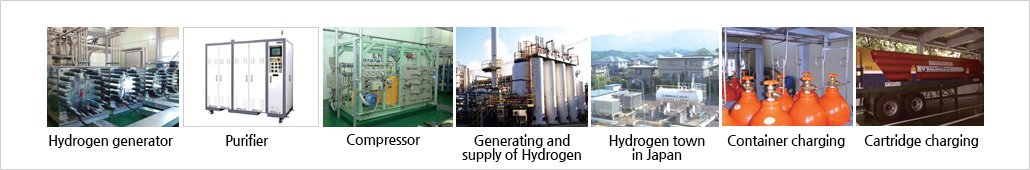

Hydrogen Generation Plant

Hydrogen is not for the future, it is a reality.

On-site supply of hydrogen to metal refining industry and using high purity oxygen

It is the way of enhancing the capability of cost saving

It is a facility to distribute, supply and use the compressed gas containers that are from the generated hydrogen and oxygen from the water. The highly purified hydrogen can be used for cooling semi-conductors and turbines. Moreover, the oxygen can be used for food science such as synthesis of protein.

Technical specifications

| MODEL | EHP™-20 | EHP™-50 | EHP™-100 | EHP™-300 |

|---|---|---|---|---|

| Hydrogen capacity (N㎥/h)* | 20 | 50 | 100 | 300 |

| Oxygen capacity (N㎥/h) | 10 | 25 | 50 | 150 |

| Electrolyzer(Set) | 10N㎥/h x 2 | 10N㎥/h x 5 | 10N㎥/h x 10 | 15N㎥/h x 20 |

| Supply pressure (MPa) ** | 0.1 ~ 0.8 | |||

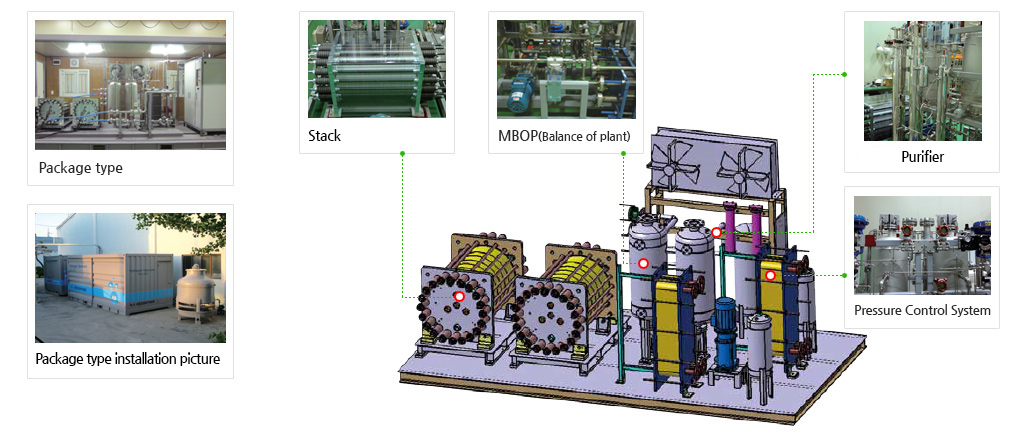

- Components of Hydrogen plant

-

- · Hydrogen/Oxygen generator : 20, 50, 100, 300 N㎥/h, large

- · Hydrogen/Oxygen compressor : more than 25MPa

- · Hydrogen/Oxygen storing device : Tube Trailer

- · Purity(Impurities except hydragen) : less than 50 ppm

- · Hydrogen/Oxygen supply pressure : 0.1 ~ 0.8 MPa

- Advantages of On-site method:

-

- · Easy to use and reducing logistic cost

- · Does not need a large storage tank

- · Stable operating process by smooth supply of hydrogen

- · Generating procese in hydrogen generation plant contribute to quality stabilization

Generating process in Hydrogen plant

Purpose of Hydrogen generating device

-

- Chemical & food process

-

- Combine hydrogen during the process of changing physicochemical features of food, alcohol, and etc.

- Food industry / Chemical industry

-

- Heat treatment/Brazing

-

- Used as reduction ambient gas (mixing with nitrogen)

- Used to remove oxygen and make reduction atmosphere to combine bimetallic with medium

- Steel manufacture/Metal/Assembling/SUS production/Assembly of metals

-

- Powder metallurgy sintering

-

- Use nitrogen with hydrogen to make reduction atmosphere without carbon to heat the powdered metallurgy parts

- Powdered metallurgy manufacture / Automobile

-

- Manufacturing of refractory metals

-

- Hydrogen used to manufacture pure tungsten or molybdenum through the reaction with metallic oxides

- Manufacturing tungsten/molybdenum

-

- High Temperature Melting

-

- Hydrogen burning reaction with hot flame when manufacturing optical fibers and crystal

- Electronic industry/ Telecommunication industry

-

- Fuel

-

- Burned with oxygen for space propulsion

- Aerospace/Defense industry

- Hydrogen fuel cell car

-

- Cooling of generator

-

- Used to remove frictional heat and electric heat

- Electrical facilities

-

- Semi-conductor

-

- Used to extract one crystal layer from the top of the substrate in manufacturing process of integrated circuit

- Semiconductor industry/ Electronic industry

-

- Poly-silicon crystallization

-

- Used as carrier gas in a process where poly-silicon is educed on top of the substrate

- Poly-silicon manufacturer

Example of Hydrogen plant operation

-

[ Hydrogen generator – 10Nm3 ]

-

ㆍEM Solution is a leading company of manufacturing hydrogen generator in domestic market

through its R&D for many years.

ㆍIt secured electrolysis system operating technology by using solar generating electricity.

ㆍIt obtained patent of electrolytic stack structure and design which is core technology of

hydrogen generator.

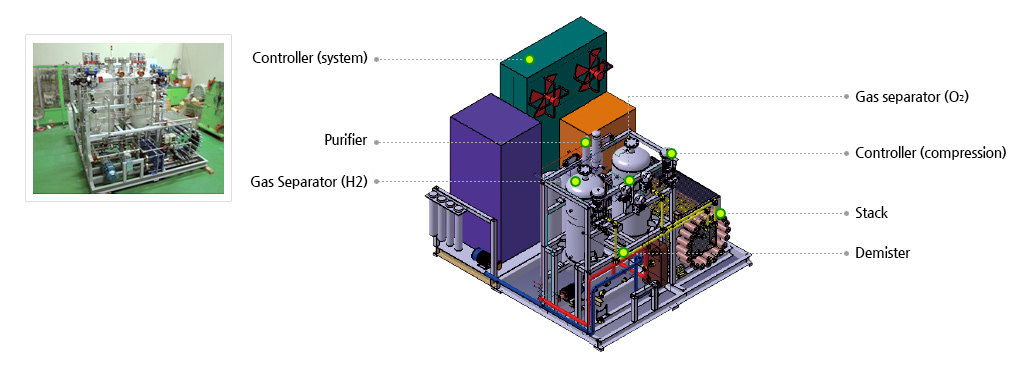

Alkali type hydrogen generation plant (purity module embedded)

It is possible to supply safe and stable hydrogen gases with an eco-friendly system which does not discharge any green-house gases. Moreover, low manufacturing cost of hydrogen leads to cost reduction. There are no risks of storing high pressure gases and introduction of an automatic control system for all manufacturing process of hydrogen, enhance users’ convenience. However, EMS ensures its stability and safetiness through certified durability test.

Technical specifications

| MODEL | EHG-302A | EHG-502A | EHG-103A |

|---|---|---|---|

| Capacity(N㎥/h) Capacity* | 3 | 5 | 10 |

| Design Pressure(MPa) Design Pressure | 0.99 MPa | ||

| Hydrogen Purity(%) Hydrogen Purity | 99.5% (Option : able to manufacture more than 99.999%) | ||

| Power supply frequency | 60HZ / 3Ø (Option : 50HZ order made) | ||

| Power consumption(kWh) | 21 | 35 | 70 |

| Voltage | Select among 220V / 380V / 440V | ||

| Supply volume(ℓ/h) | 3 | 5 | 10 |

| Quality of service water(㎲/cm) | 0~10 | ||

| Size(W×B×H) | 1,380×1,200×1,850 | 1,380×1,200×1,850 | 1,450×1,350×1,960 |

| Weight(kg) | 1,200 | 1,500 | 2,400 |

Mechanism of Hydrogen Generator

-

-

The alkali type hydrogen generator uses electrolyte of potassium

hydroxide and the separation film is installed between positive and

negative poles to prevent them from being mixed.

Water is electrolyzed to produce hydrogen ion (H+) and

hydroxyl ion (OH-), and the hydrogen ion reacts with

the electrons to generate hydrogen gases at negative pole.

The hydroxyl ion (OH-) passes through the ion exchange membrane

and move to positive pole in order to generate the oxygen gas.

Technical specifications

| MODEL | EHG-203A | EHG-403A | EHG-603A | EHG-803A |

|---|---|---|---|---|

| Capacity(N㎥/h) | 20 | 40 | 60 | 80 |

| Design Pressure(MPa) | 0.99 MPa | |||

| Hydrogen Purity(%) | 99.5% (Option : able to manufacture more than 99.999%) | |||

| Frequency | 60HZ / 3Ø (Option 50HZ order made) | |||

| Power consumption(kWh) | 140 | 280 | 420 | 480 |

| Voltage | Select among 220V / 380V / 440V | |||

| Supply volume(ℓ/h) | 20 | 40 | 60 | 80 |

| Quality of service water(㎲/cm) | 0~10 | |||

| Size(W×B×H) | 3,000×9,000×2,600 | 3,000×12,000×2,600 | 3,000×12,000×2,600 3,000×3,000×2,600 |

3,000×12,000×2,600 3,000×3,000×2,600 |

| Weight(kg) | 9,000 | 12,000 | 15,000 | 16,000 |

PACKAGE TYPE